Please add my whatsapp +86-13062580091 to get best price

The circular saw blade is an essential tool in both professional and DIY woodworking. Its design and functionality enable precise, efficient cuts through various materials, making it a staple in construction, carpentry, and metalworking. Understanding the types of circular saw blades and their applications can enhance cutting accuracy and project efficiency.

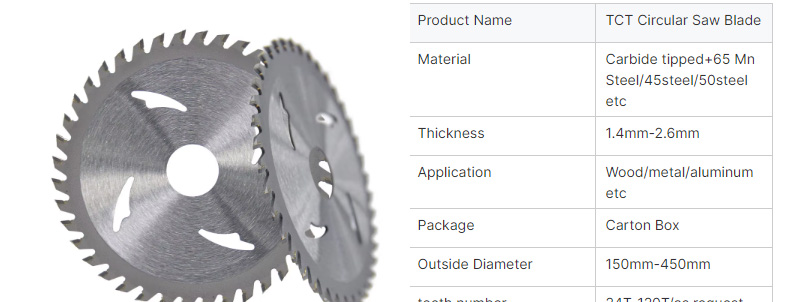

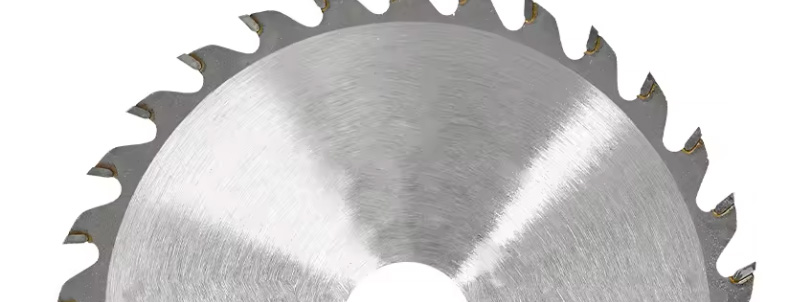

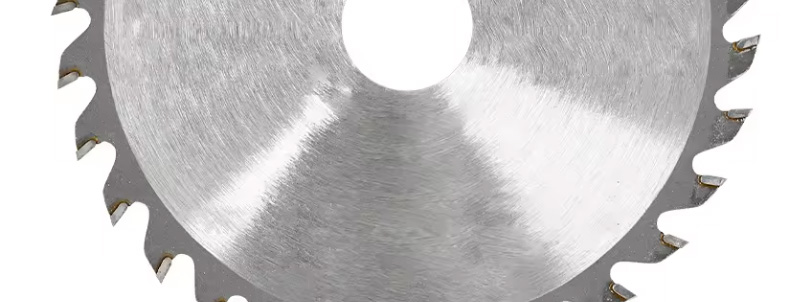

A circular saw blade features a round, toothed blade that rotates at high speeds. Mounted on a circular saw, this blade cuts through materials with a continuous, rotary motion. The teeth on the blade are designed to slice through different substances, and their configuration varies depending on the intended application. The blade’s material and tooth design are critical in determining its performance and durability.

General Purpose Blades:These blades are versatile and designed for a range of cutting tasks. They are commonly used for cutting wood, plywood, and some non-ferrous metals. General-purpose blades typically have a balanced tooth configuration that provides a good combination of cutting speed and finish quality.

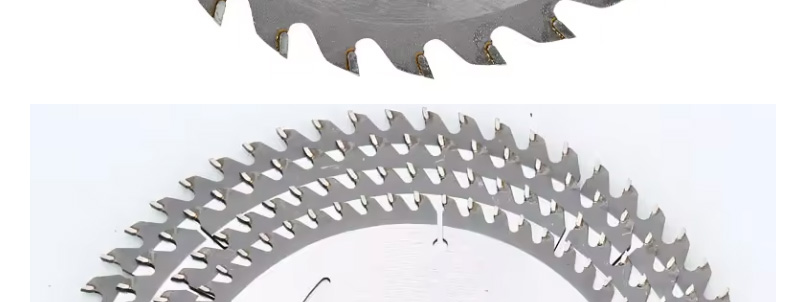

Crosscut Blades:Crosscut blades are designed with a high number of teeth, which are ideal for cutting across the grain of wood. They produce a smoother finish compared to other blades and are used for creating precise, clean cuts in wood and wood-based materials.

Rip Blades:Rip blades have fewer teeth with a more aggressive tooth design, making them suitable for cutting with the grain of the wood. They are optimized for faster, more efficient cuts in lumber and can handle thicker pieces of wood with ease.

Combination Blades:As the name suggests, combination blades are designed to handle both crosscutting and ripping tasks. They feature a tooth pattern that balances the needs of both types of cuts, making them a versatile option for various woodworking projects.

Metal Cutting Blades:These blades are specifically designed to cut through metal materials, including aluminum and steel. They are made from high-speed steel (HSS) or carbide-tipped materials to withstand the toughness of metals and deliver clean cuts.

Diamond Blades:Diamond blades are equipped with diamond segments that allow them to cut through hard materials like concrete, masonry, and tile. They are used in construction and renovation projects where precise cutting of hard materials is required.

Woodworking:In woodworking, circular saw blades are used for cutting lumber, plywood, and other wood materials. The choice of blade depends on the type of cut needed—whether it’s a smooth finish or a rough cut.

Construction:Circular saw blades are indispensable in construction for cutting materials like concrete, masonry, and metal. Different blade types are chosen based on the specific material and cutting requirements.

Metalworking:Metal cutting blades are used in metalworking shops for cutting steel, aluminum, and other metals. Their durability and precision are essential for creating metal parts and components.

DIY Projects:For DIY enthusiasts, circular saw blades offer the ability to tackle various home improvement and craft projects. Whether building furniture or remodeling a space, having the right blade makes a significant difference in project outcomes.

Proper maintenance of circular saw blades involves regular cleaning and sharpening. Keeping blades sharp ensures efficient cutting and extends their lifespan. Additionally, safety precautions should always be followed to prevent accidents, including using personal protective equipment (PPE) and ensuring the saw is properly secured.

The circular saw blade is a fundamental tool in many cutting applications, offering versatility and precision across various materials and industries. By understanding the types of blades and their specific uses, users can optimize their cutting processes and achieve the best results in their projects. Regular maintenance and adherence to safety practices further ensure the effectiveness and longevity of this indispensable tool.

Contact: Tony

Phone: +8613062580091

E-mail: [email protected]

Whatsapp:+8613062580091

Add: Yushan High-tech Zone Maanshan City Anhui Provnice China

We chat