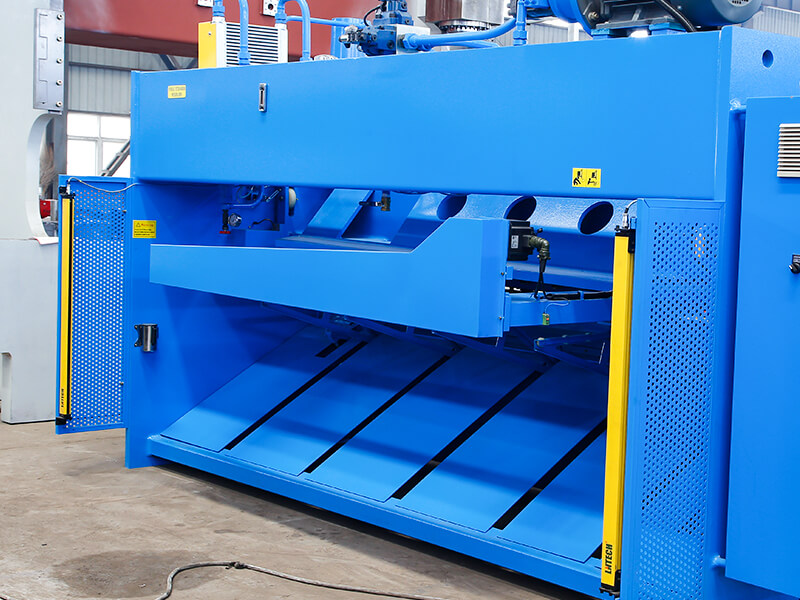

Guillotine shear is the type of plate shears widely selected by global purchasers because it can adjust the blade clearance and angle. When cutting plates with a thickness of more than 13mm, it has more advantages in terms of price and cutting effect.

The design of the shearing machine includes a box bed frame completely welded with the workbench.

The frame can produce high stiffness to balance the torque load generated by shear force.

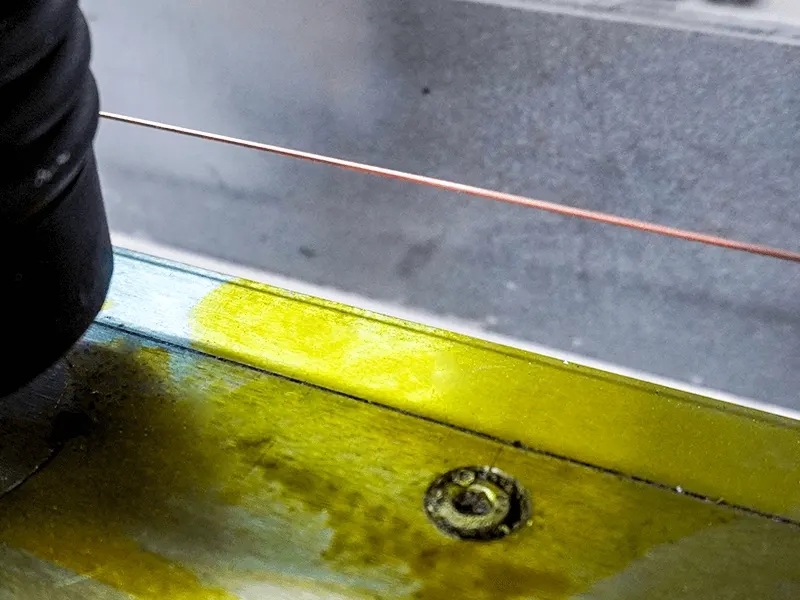

Vertical linear movement relative to the lower blade to ensure that the shear sheet has less distortion and more accurate straightness.

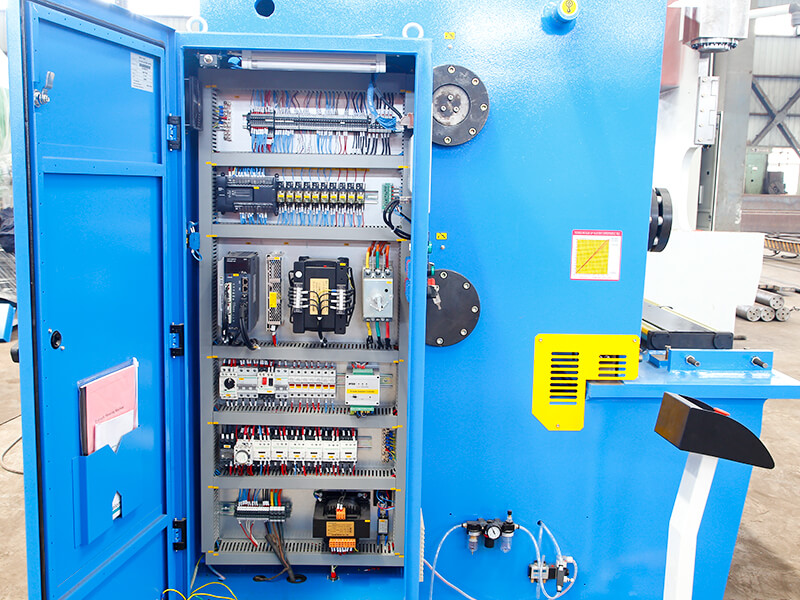

The controller is DAC360 CNC system of Delem brand in the Netherlands (now upgraded to DAC360T touch screen);

The back stop, blade angle and blade gap can be controlled and adjusted in the system;

ELGO P40T and E21S digital display controller can also be selected.

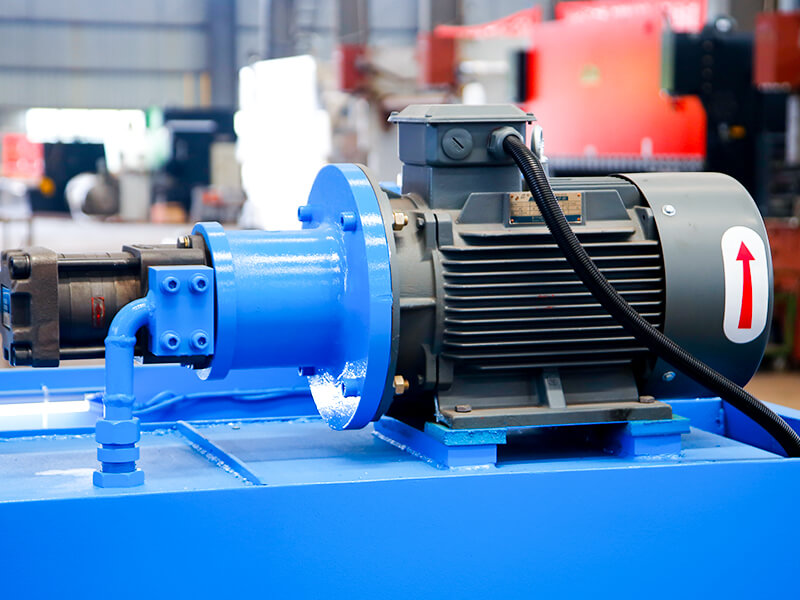

High performance main motor can be equipped with international brand such as Siemens or Chinese famous brand Wannan.

Voltage customization, such as 3-phase / 220 V / 60 Hz, 3-phase / 380 V / 60 Hz, 3-phase / 415 V / 60 Hz, etc.

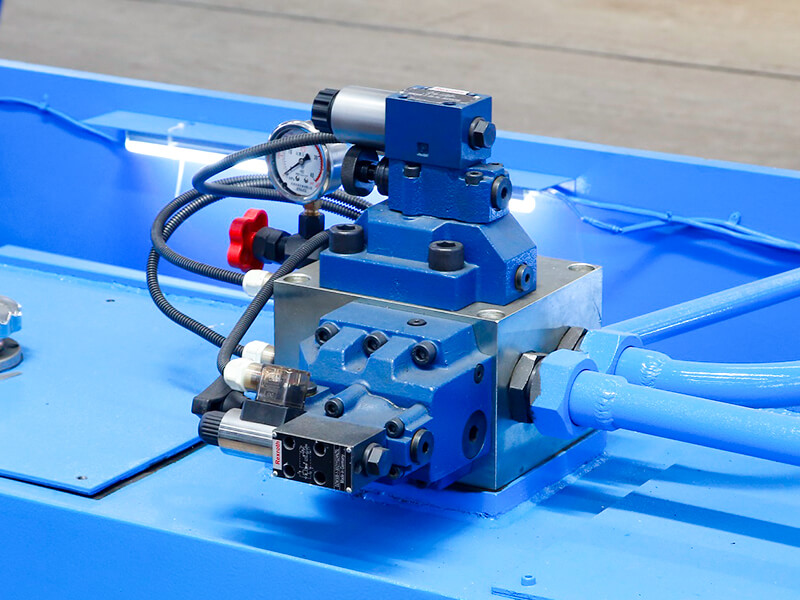

International brand Rexroth hydraulic valve block is adopted;

With oil pressure overload protection, oil leakage and valve jamming are rare;

Real time oil pressure monitoring to ensure smooth oil circuit and stable running of the equipment.

The design of feed port complies with international safety standards;

The minimum feeding height is the sheet thickness, and the maximum is the sheet thickness plus 20-25mm. There are adjustable height screws to adjust the feeding height;

The front fence and side guardrail ensure safe operation.

It is equipped with light alignment device, which is convenient for marking and shearing, and can steplessly adjust the stroke of the blade holder.

Pneumatic rear support device and rear light curtain protection device are optional.

The automatic rear support plays a supporting role in cutting the thin plate to ensure the cutting accuracy and surface finish of the plate.

The rear light curtain protection protects personal safety during the operation of the machine and complies with international safety standards.

The motorized shearing angle adjusting device saves the trouble of manual adjustment and can automatically adjust the shearing angle according to the plate thickness.

High-quality electrical components are adopted, which are stable and durable with long service life.

The rear servo reduction motor has good quality and fast positioning speed of simulation operation.

The rear servo reduction motor has good quality and fast positioning speed of simulation operation.

It is more convenient and faster. There are two models: automatic and manual, which are convenient for customers to choose.

Contact: Tony

Phone: +8613062580091

E-mail: [email protected]

Whatsapp:+8613062580091

Add: Yushan High-tech Zone Maanshan City Anhui Provnice China

We chat