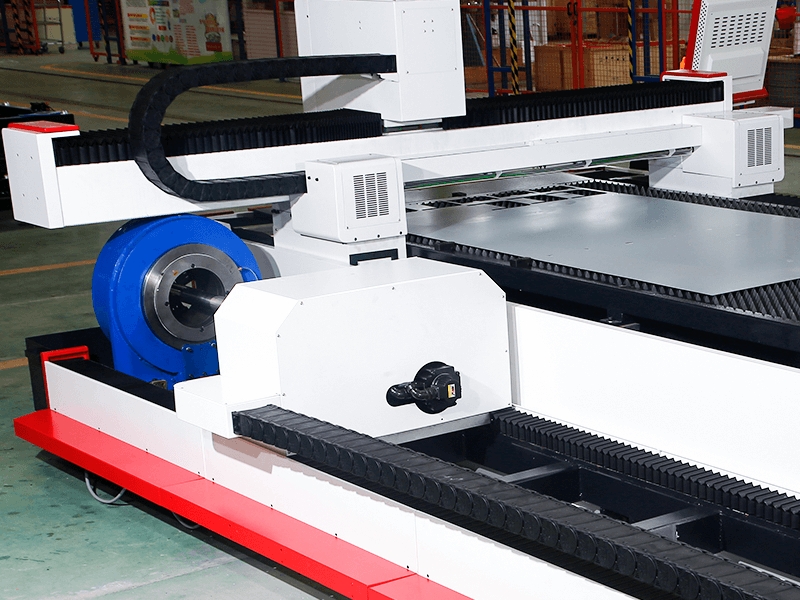

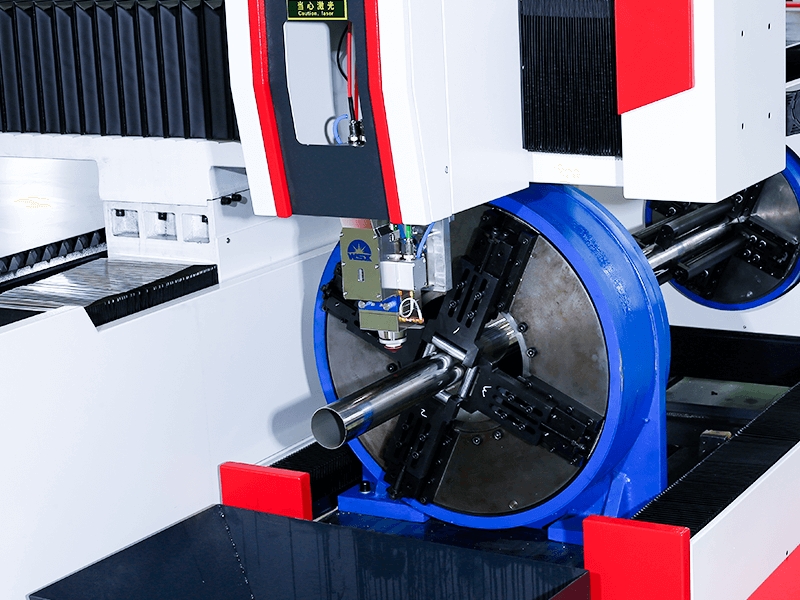

The integrated design for the cutting of the plate and tube. The single piece of equipment perfectly realizes the cutting process of the flat plate, the round pipe and the square pipe, with high degree of refinement, high speed, small slit, smooth section, simple operation and low energy consumption, and is suitable for continuous processing in large quantities.

The internal structure adopts hollow + fish scale anti burning to protect the overall structure.

It is welded by multiple rectangular pipes, and stiffeners are set inside the pipe to increase the strength and tensile property of the bed.

The whole frame is annealed at high temperature, shot blasted at high speed, and stress relief technology is applied to effectively avoid bed deformation and ensure no deformation after 20 years of use.

High rigidity and lightweight design optimized by finite element analysis; High speed, good dynamic characteristics and fast acceleration.

It is made of high-performance manganese steel material by butt welding. Through ingenious structural design, the rigidity of the beam during high-speed operation is improved to ensure the overall stability of the laser cutting machine in the process of cutting at high speed.

After heat treatment, it can achieve strong rigidity and strength, with excellent seismic resistance and stability, and effectively ensure that the beam will not deform in the process of long-term use.

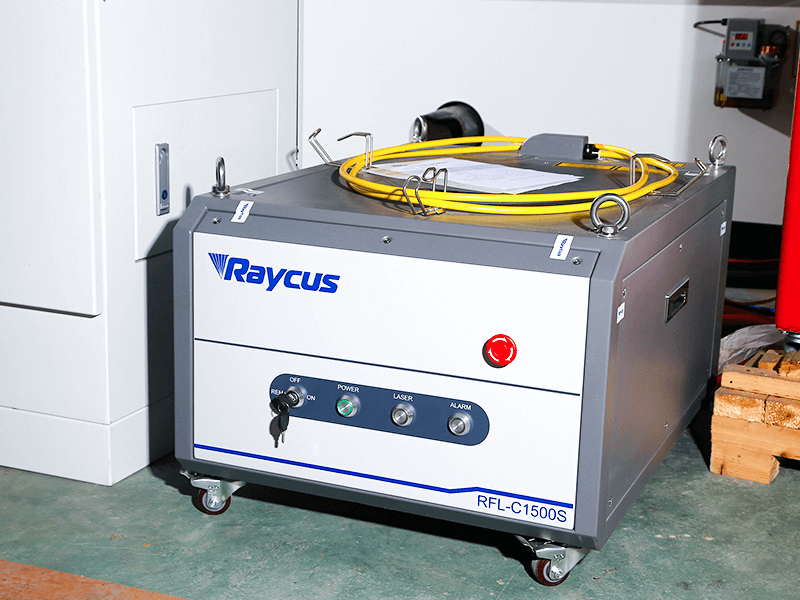

The brand of our fiber laser source including Raycus (China), n-Light (USA), IPG (Germany), with the power from 1000W to 20,000W.

Constant BPP in full power range, good beam quality, small spot, more than 30% electro-optic conversion efficiency;

Modular "plug and play" design, compact and firm structure, convenient installation.

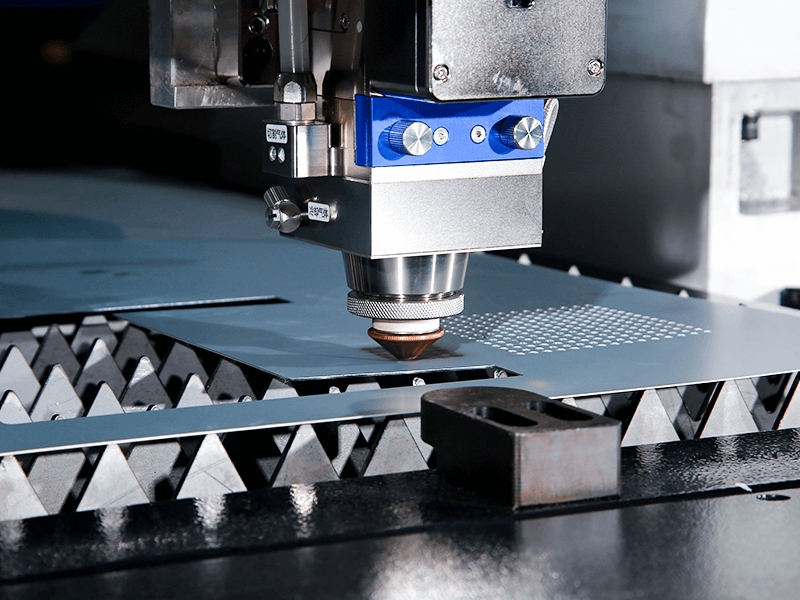

The auto focusing laser cutting head can adjust the focus according to the material thickness.

It is suitable for multi focus section, shorten the cutting time and improve the cutting quality.

The anti-collision protection structure of the cutting head is patented, and the waste cutting micro connection prevents the plate from warping, so as to realize the high-speed operation and high stability during cutting.

The pneumatic chuck is clamped with one key to open the clamp, and automatically centering. The speed is 3 times that of the electric chuck, reducing the waiting time for loading and unloading;

Pneumatic clamping opening, large and constant clamping force, no looseness and slip of heavy pipe, ensuring cutting accuracy;

It can be used for cutting common square tube (Φ20 * 20 - Φ320 * 320mm), round tube (Φ20-320mm) and rectangular tube (rectangular diagonal ≤ 220mm).

Cypcut cutting software, China's cutting software specially designed for fiber laser cutting machine.

It has the advantages of convenient installation, simple debugging and excellent performance, and supports the speed adjustment with power.

It can set the import linear speed separately and has a powerful cutting process database.

The timed automatic lubrication system can automatically start and add lubricating oil according to the working time, which is convenient and fast.

With the functions of over temperature alarm, flow protection, water level protection and other safety alarm tips.

It is used to reduce the overall temperature inside the electrical cabinet and ensure the stable operation of the electrical cabinet.

Contact: Tony

Phone: +8613062580091

E-mail: [email protected]

Whatsapp:+8613062580091

Add: Yushan High-tech Zone Maanshan City Anhui Provnice China

We chat