It is mainly used for cutting full-length and extra wide sheets. Our swing beam type shears still remain the pacesetters in the price/quality ratio market of today. All our QC12 series shears are equipped with power rake angle adjustment function.

The whole machine adopt steel plate welding structure, hydraulic transmission, accumulator return, with convenient operation, reliable performance and beautiful appearance.

The special economical numerical control system for the plate shearing machine is adopted, and the DAC310T system of Delem company in the Netherlands is optional, which is able to control the cutting angle and blade clearance automatically.

High performance main motor can be equipped with international brand such as Siemens or Chinese famous brand Wannan.

Voltage customization, such as 3-phase / 220 V / 60 Hz, 3-phase / 380 V / 60 Hz, 3-phase / 415 V / 60 Hz, etc.

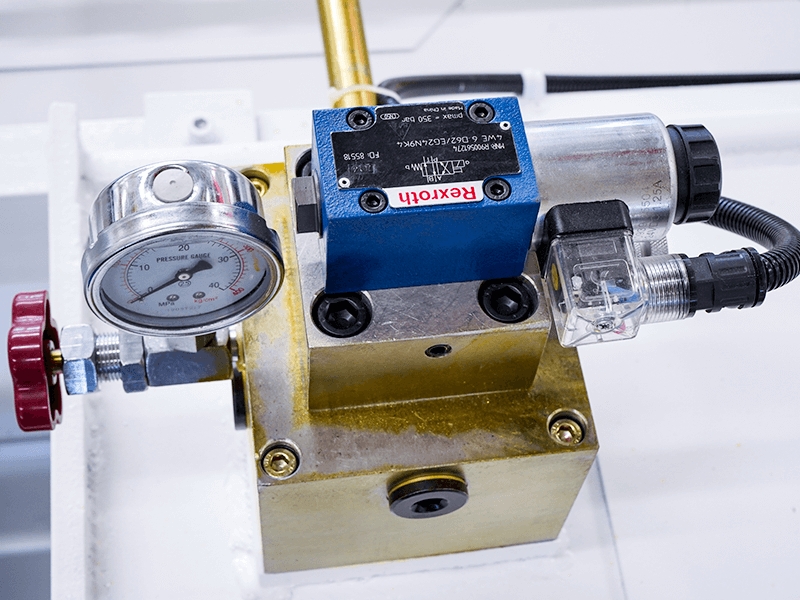

International brand Rexroth hydraulic valve block is adopted;

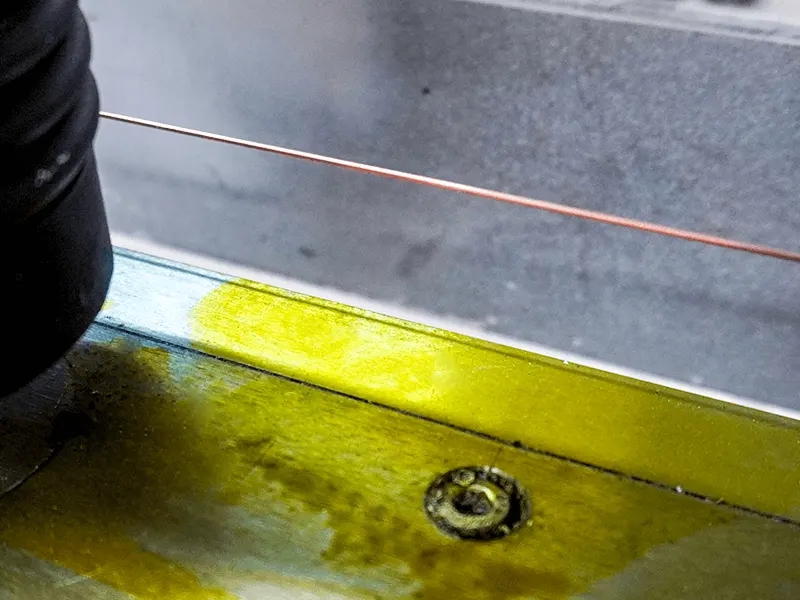

With oil pressure overload protection, oil leakage and valve jamming are rare;

Real time oil pressure monitoring to ensure smooth oil circuit and stable running of the equipment.

The design of feed port complies with international safety standards;

The minimum feeding height is the sheet thickness, and the maximum is the sheet thickness plus 20-25mm. There are adjustable height screws to adjust the feeding height;

The front fence and side guardrail ensure safe operation.

The standard alignment device uses the machine light to project the line shadow on the sheet to achieve high cutting straightness and replace the traditional line drawing cutting.

The ball type front support reduces the friction between the plate and the table, and ensures the smoothness of the plate surface;

The feeding is more convenient and fast, and the cutting efficiency is improved.

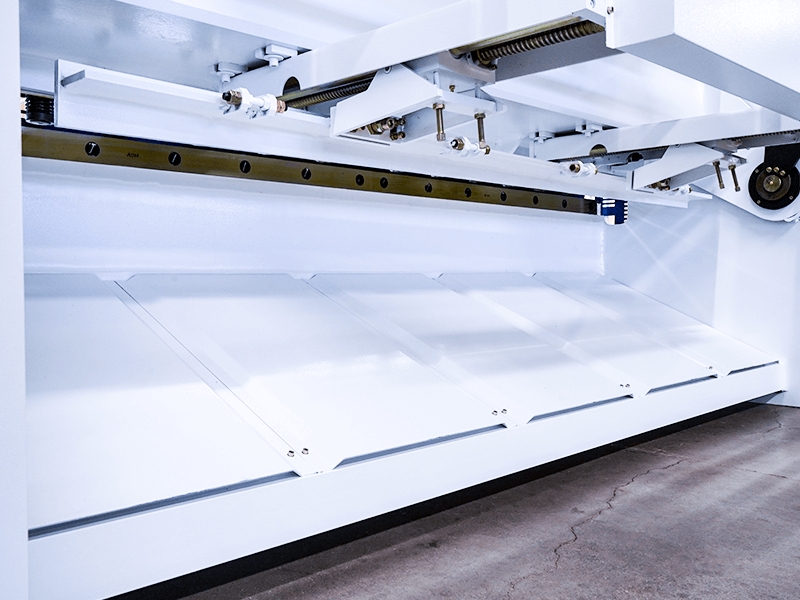

The heavy-duty backgauge design ensures the collision resistance of the back stopper and is not easy to deform.

The convenient backgauge rack facilitates the taking of cutting materials.

Manual and automatic back stop lifting function can be selected to meet the cutting requirements of long materials.

It is convenient for customers to cut wide sheets, which can be closed with one key when not in use.

Photoelectric protection to protect personal safety, especially finger safety.

It is more convenient and faster. There are two models: automatic and manual, which are convenient for customers to choose.

In high temperature environment, the machine can be used continuously for a longer time

Contact: Tony

Phone: +8613062580091

E-mail: [email protected]

Whatsapp:+8613062580091

Add: Yushan High-tech Zone Maanshan City Anhui Provnice China

We chat