A few years ago, DF team realized that energy conservation, efficiency and environmental protection would be the trend, so we developed and produced WAD series press brakes. In the traditional press brake, the pump and motor will run continuously, but in the servo system of our WAD series press brake, as long as the plunger is at rest, the pump and main motor will be at rest. This saves a lot of energy without affecting productivity.

press brake also call press brake machine,hydraulic press brake,press brake for sale,cnc press brake,metal press brake,sheet metal press brake......

There is no doubt that it is the brain of the whole machine. We offer Delem, ESA and Cybelec brand controller, which are imported from the Netherlands, Italy and Switzerland respectively.

The efficient algorithm optimizes the running cycle of bending, reduces the time required to set the work step, and makes bending more efficient, especially for batch processing.

In addition, the system can meet 2D and 3D graphics editing.

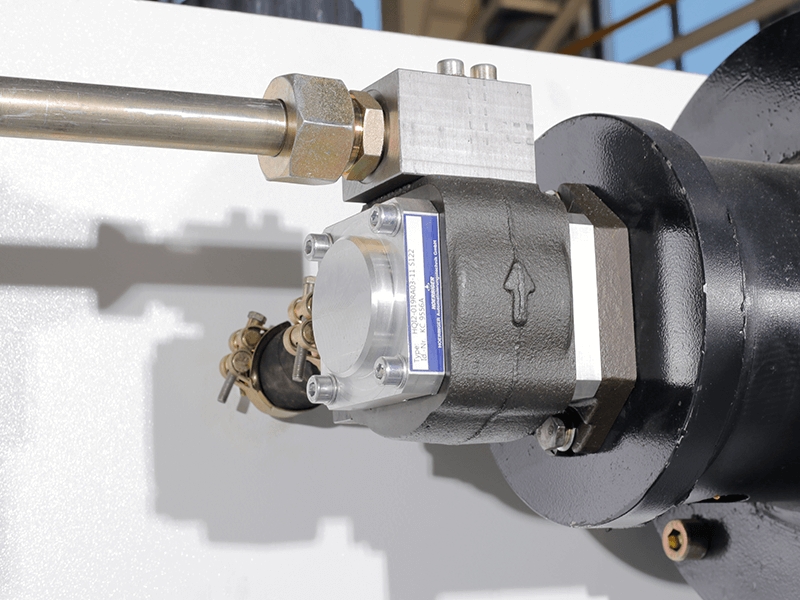

This is an electro-hydraulic servo synchronous hydraulic control system with short hydraulic cylinder spacing. It has strong anti eccentric load ability, high synchronization accuracy, low cost and high power density ratio.

The pressure of the hydraulic system can be adjusted according to the practical use to meet the requirements of bending force.

ADH adopts the well-known German brand Hawei hydraulic system, which has the characteristics of low failure rate and high efficiency.

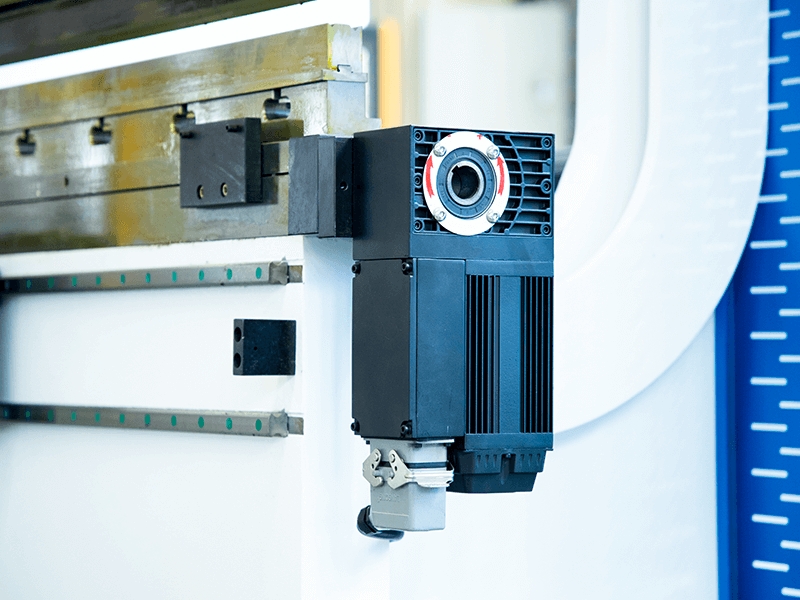

As we all know, servo motor has become the mainstream, with low energy consumption, high dynamics and improving machine production efficiency as the main goal. Compared with traditional motors, the energy consumption can be saved up to 35%, so it can bring customers the advantages of high efficiency and low operation cost.

At the same time, we also have an efficient and energy-saving motor from Siemens, Germany, which can meet the daily production needs of customers, and its work efficiency is much higher than that of ordinary motors.

The oil pump is made of high-strength cast iron, with unique internal noise reduction design, low sensitivity to oil pollution and long service life.

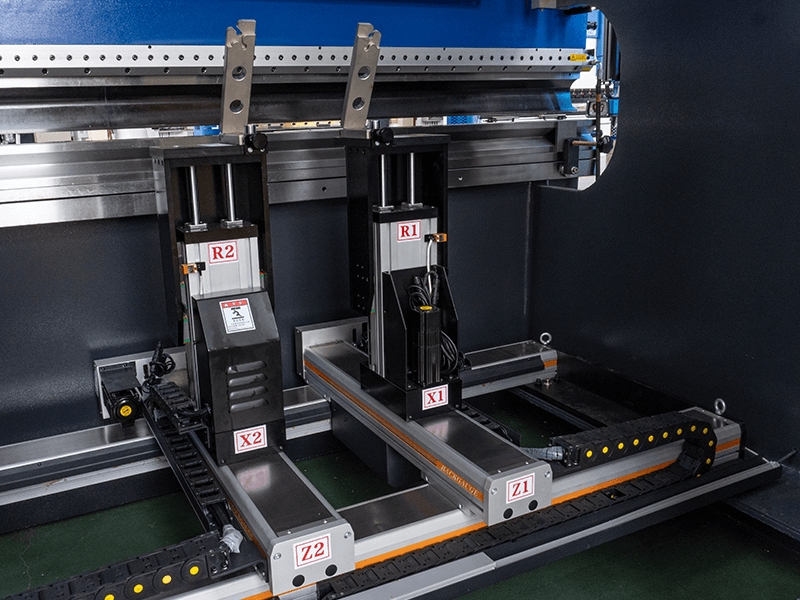

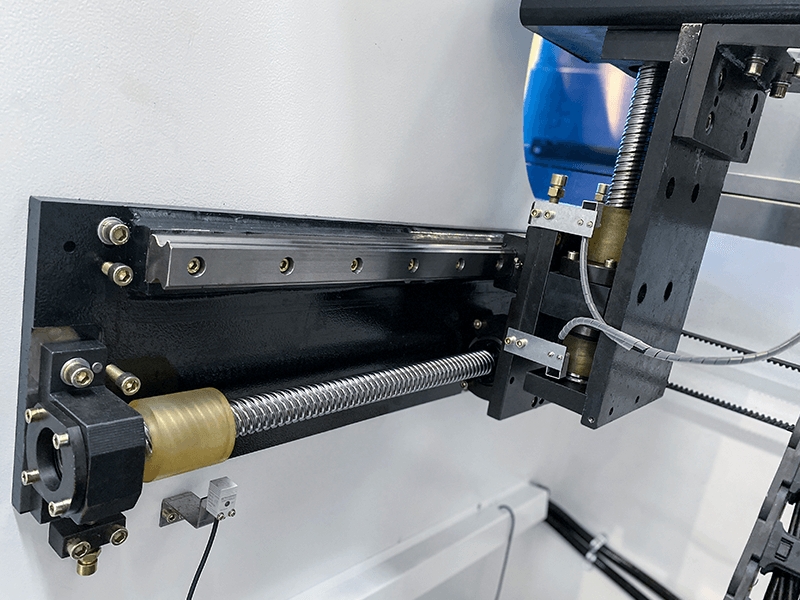

We use imported ball screw and linear guide rail to ensure that the movement accuracy of X-axis is higher than that of screw rod.

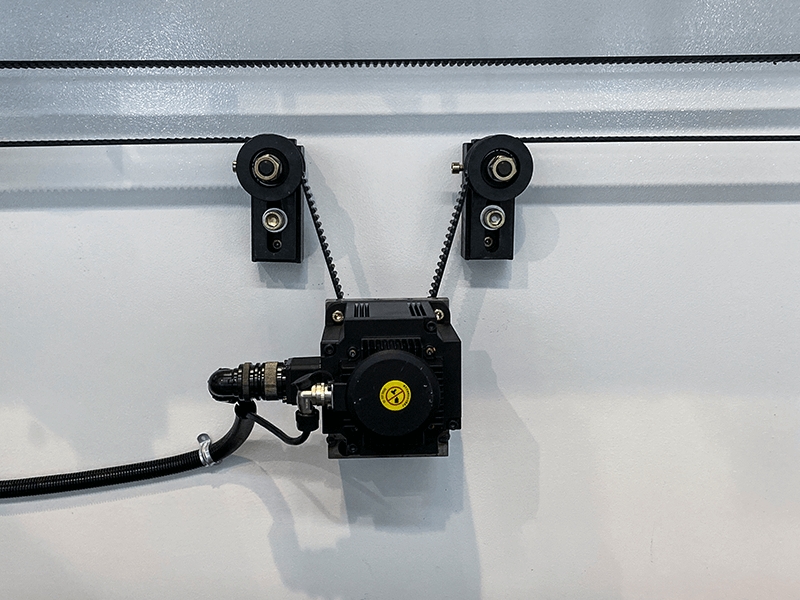

The rear stop adopts synchronous pulley mechanism controlled by servo motor instead of stepping motor.

The whole backgauge system is tempered at high temperature, which is conducive to completely eliminate the internal stress, improve the plasticity and toughness of the metal, and make you no longer suffer from any loss of accuracy caused by frame deformation.

It adopts genuine Schneider pieces imported from France, which is stable and durable with long service life;

Equipped with Estun original adaptive electrical box assembly, with strong anti-interference ability and stable electrical operation.

Independent design, calculate the compensation value according to the total deformation of the ram and worktable, so as to make the deformation curve of the bed fit perfectly with the compensation curve, and better ensure the consistency of product straightness and angle.

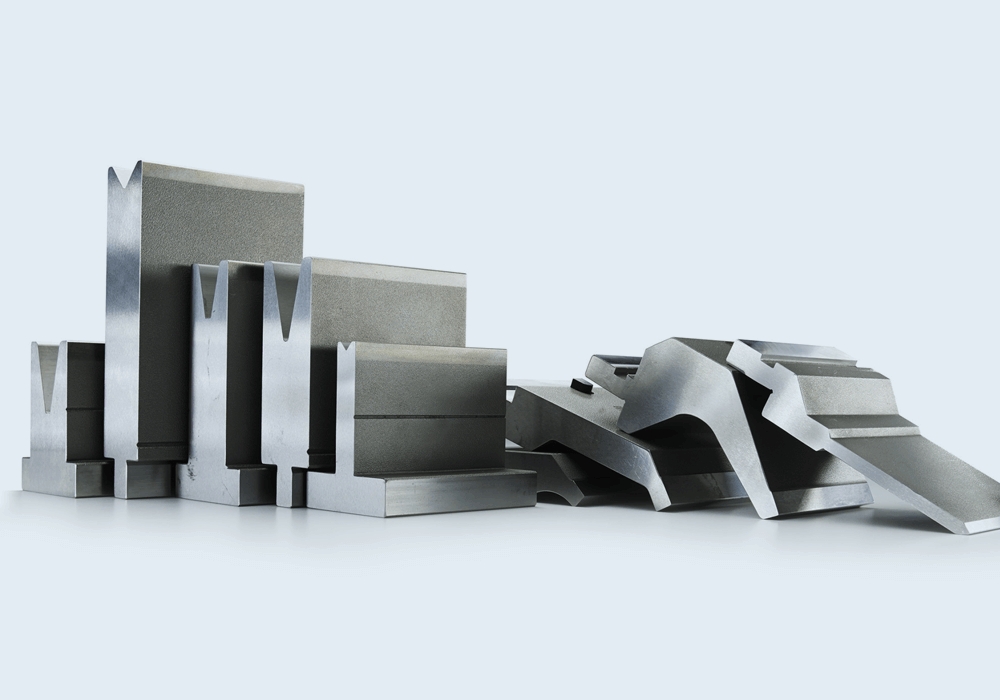

Press brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate toolings according to different bending requirements of customers.

Quickly change the top punch to save time

Ball screw and linear guide rail are adopted to ensure the smooth operation of the machine.

The servo motor controls the Y-axis moving with higher accuracy.

Contact: Tony

Phone: +8613062580091

E-mail: [email protected]

Whatsapp:+8613062580091

Add: Yushan High-tech Zone Maanshan City Anhui Provnice China

We chat