NC press brake is an economical hydraulic press brake machine with competitive price, convenient installation, simple operation and convenient after-sales maintenance. These advantages make NC press brake popular with most customers.

Estun E300P series can control X and Y axis and the bending steps can be editted in the controller;

In addition, Etune E300P, Delem DA41T and Cybelec CT8 controller have additional angle programming functions, touch screen and R-axis control functions, which make the bending easier.

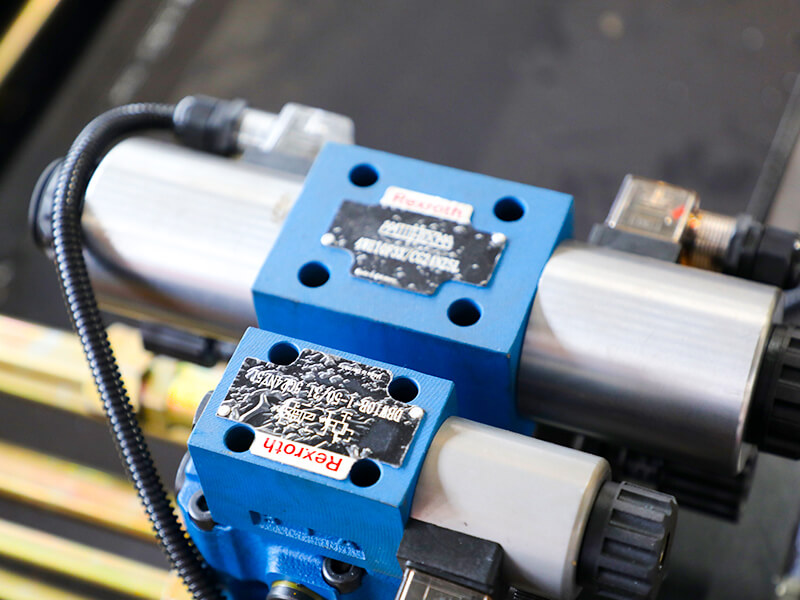

High quality hydraulic valve (Rexroth brand) is adopted, which is resistant to high pressure, durable and trouble free.

It can realize the actions of ram rapid descent, slow descent, bending at working speed, rapid return and emergency stop of ram in the process of up and down.

The machine can work continuously under the rated load, the hydraulic system has no leakage and is continuously stable with high precision.

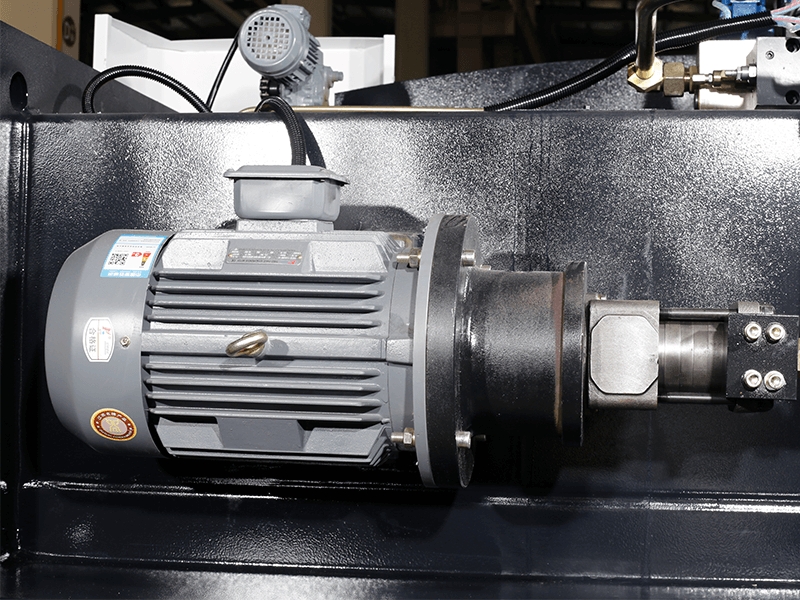

As a well-known brand in Germany, Siemens motor has the advantages of high efficiency, energy saving, large starting torque, good performance, low noise, low vibration, high reliability, power level and installation size in line with IEC standards and convenient use and maintenance.

We can customize the power and voltage according to the customer's local voltage.

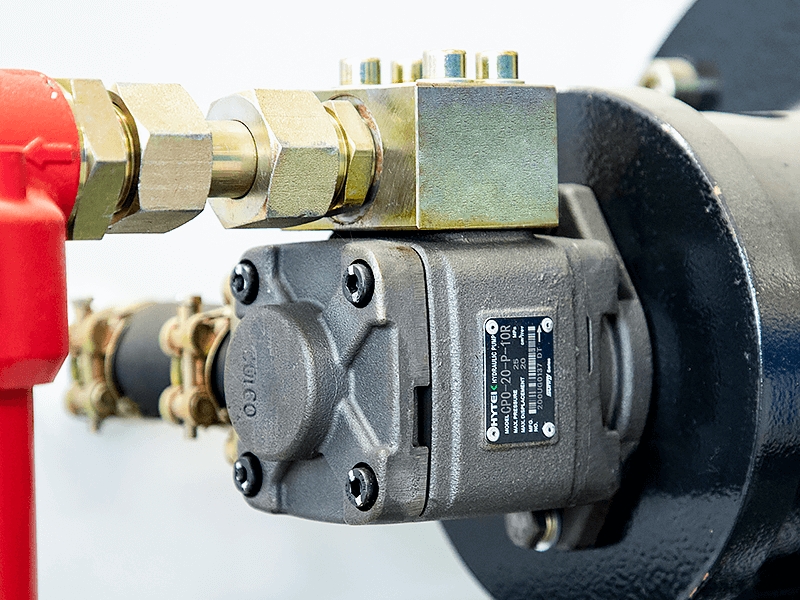

The oil pump adopts (USA Sunny) gear pump with low noise, made of high-strength cast iron, unique internal noise reduction design and can withstand high pressure.

Low sensitivity to oil pollution to ensure long service life.

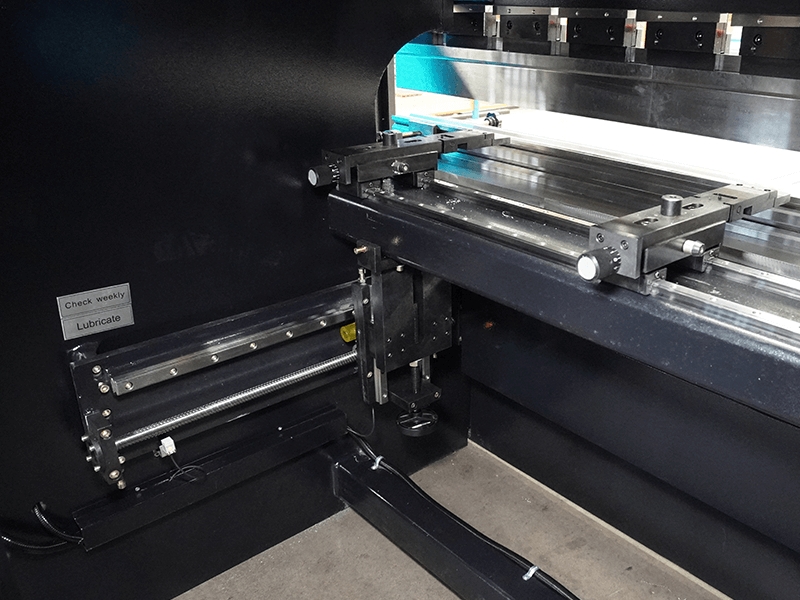

Independently designed high-precision rear stop assembly, equipped with high-precision ball screw, adjustable stop finger and manual lifting, which can adapt to different punches.

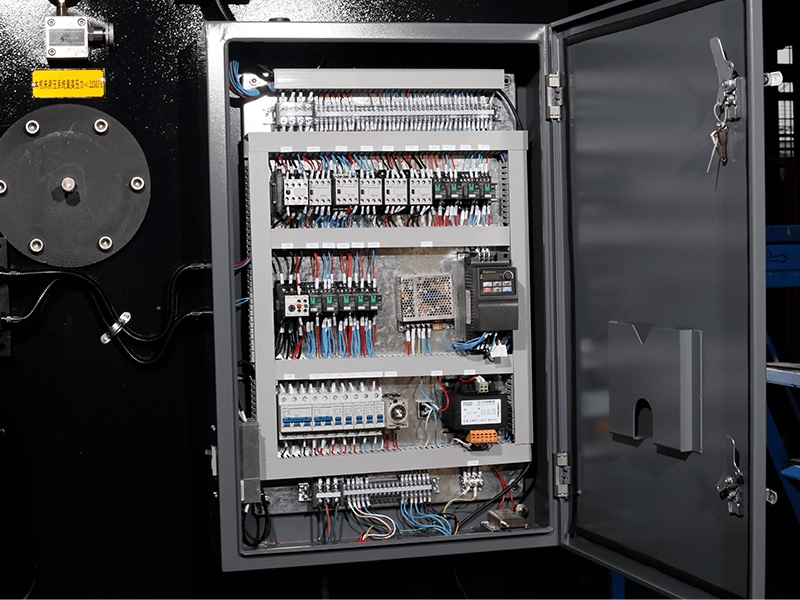

Adopts genuine Schneider pieces imported from France, which is stable and durable with long service life;

Equipped with Estun original adaptive electrical box assembly, with strong anti-interference ability and stable electrical operation.

The mechanical compensation worktable can effectively eliminate the influence of ram deformation on bending accuracy by adjusting the bulge at each position in the middle (multi-point compensation worktable / manual deflection compensation worktable), and correct the angle error at different positions in the middle.

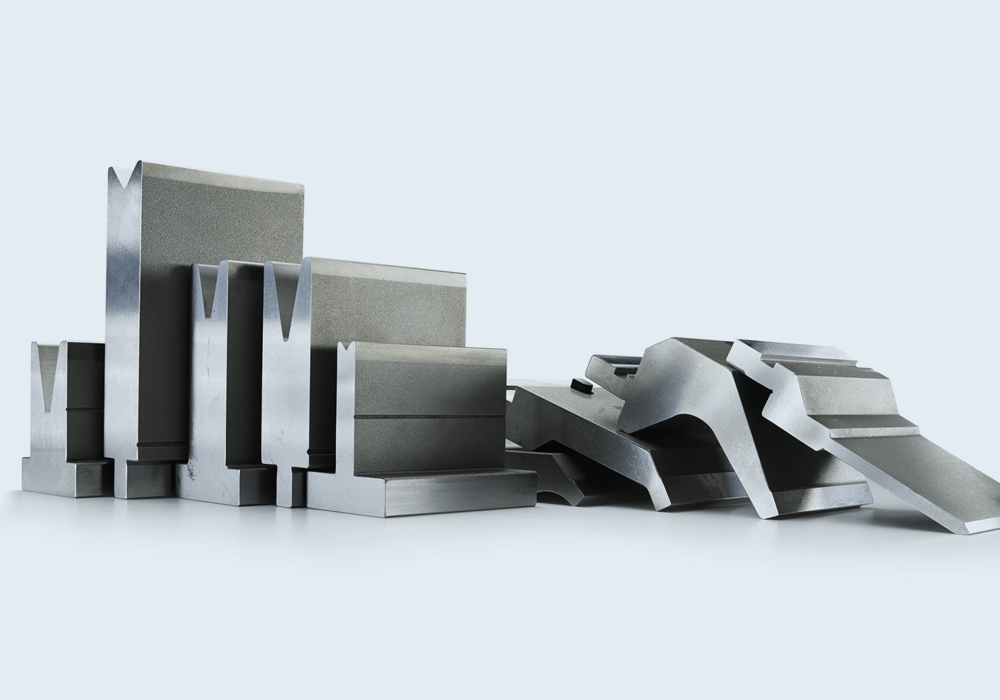

Press brake punches and dies will be one of the most important topics we discuss before you place the order. Any bending shape will be completed by a suitable set of punch and die. We can provide appropriate toolings according to different bending requirements of customers.

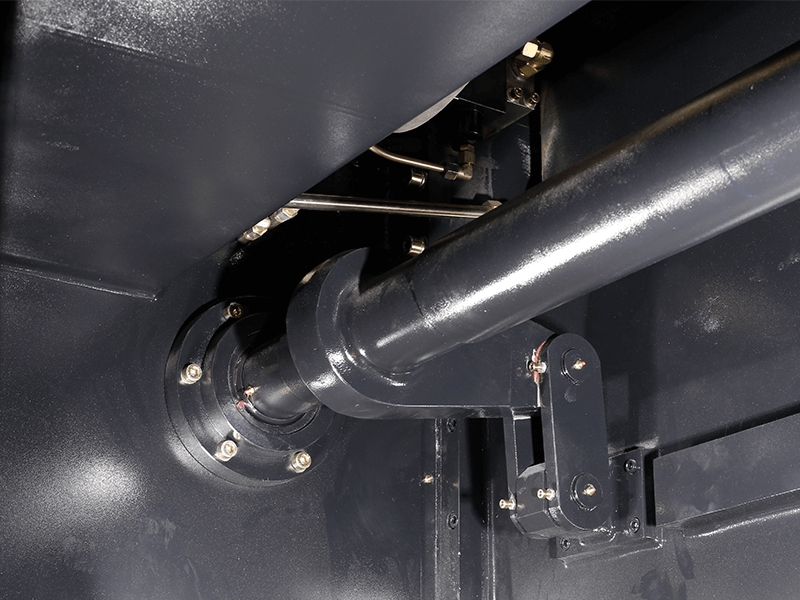

Torsion-sync principle controls the up and down movement of the ram.

Servo motor control, with higher precision.

![1669530996651569.png M4J}S%(KHVU5OTOB]$G_LX0.png](/Uploads/image/20221127/1669530996651569.png)

Contact: Tony

Phone: +8613062580091

E-mail: [email protected]

Whatsapp:+8613062580091

Add: Yushan High-tech Zone Maanshan City Anhui Provnice China

We chat